Technical Solutions

We offer automated, conveyor-driven imaging lines for herbarium sheets and pinned insects. The lines will be assembled from industrial strength components available on the market and will be configured according to the needs of the customers.

These are turn-key solutions that fit for medium and large collections that want to keep up with digitizing new accessions, and do not want to out-source digitization.

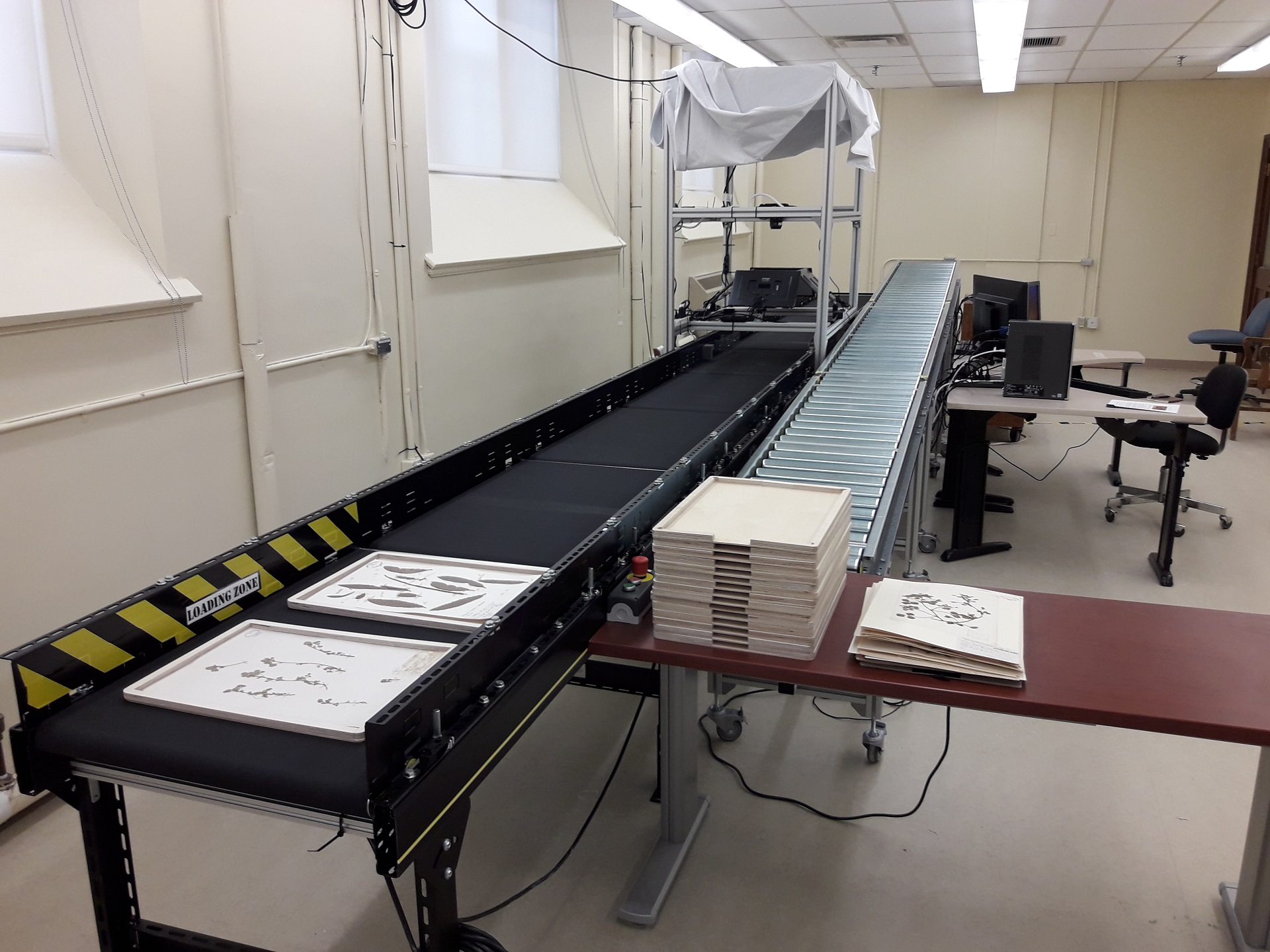

Conveyor-driven imaging lines

Systems for herbarium sheets

The rated technical performance of the herbarium line is 400 images per hour, translating to 2,800 images in a 7-hour work shift. However, the actual performance depends on several factors, such as number of operators, work organization, and how the material has been organized in boxes, folders, and within cover sheets.

For operating the line, only one person who alternates at both ends of the line is needed and still a performance of 160 images per hour can be achieved. This is due to the efficient and intelligent buffering of trays on the line. However, 2-3 operators are optimal. See the videos of Digitarium on YouTube.

Our current set-up is linear and takes a space of 9×2 meters. For efficient operation a hall of 12×5 meters is needed. Also a shorter version of 6×2 meters is available but at the expense of the buffering space.

Here is the video of the operation of our latest system for herbarium sheets! Built in June-August 2018 by Bioshare Digitization for an international customer.

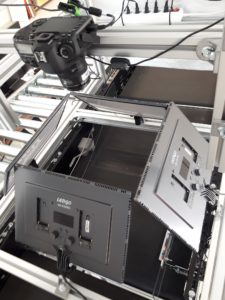

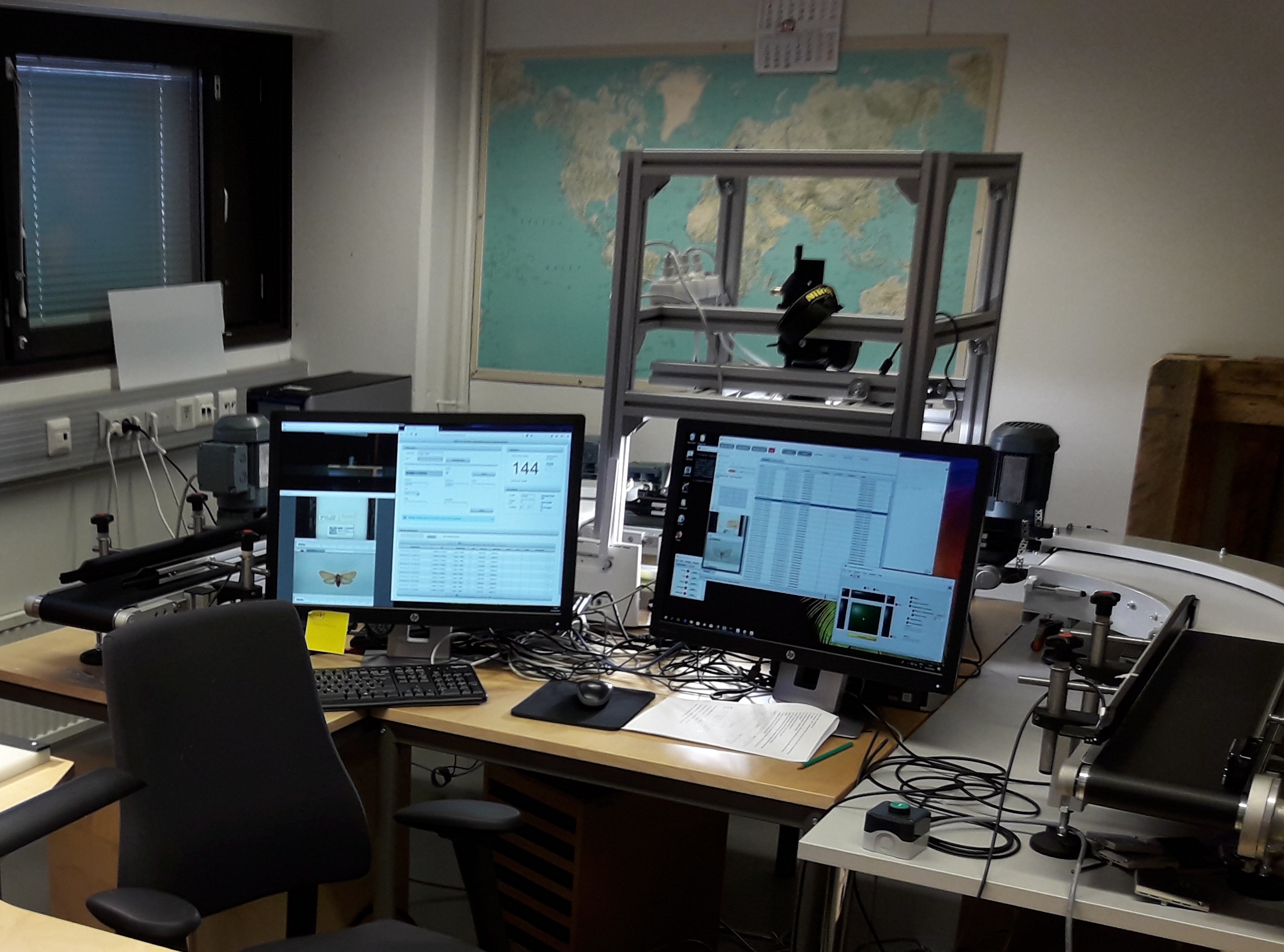

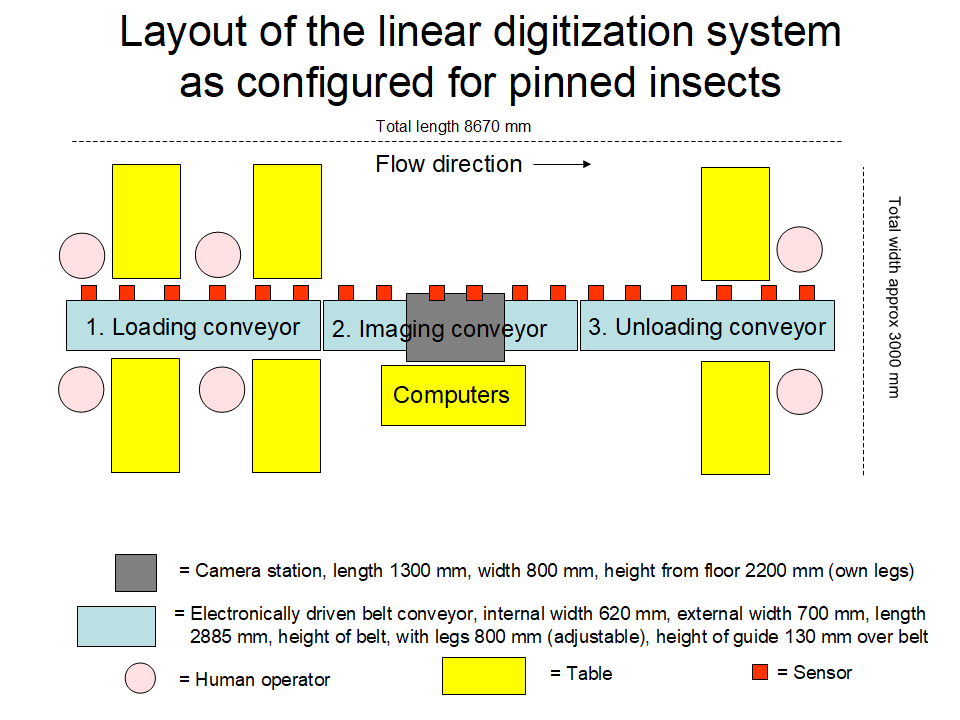

Systems for pinned insects

In our single-user automated digitization system, individual insects will be carried through the imaging line on custom pallets produced with 3D printer.

The performance depends very much whether labels of individual insects need to be handled. This is necessary for large-winged orders, such as Lepidoptera. Typical performance here is 70 specimens / hour. If labels can be left intact and photographed diagonally, performance can be much higher.

Here is a large-winged moth. The labels were removed from the pin and placed on the pallet next to the specimen.

Here is a queue of pallets carrying beetle specimens. Two shots will be made: one of the beetle from above and another from a diagonally placed camera of the beetle and the labels left intact on the pin. Underside of the labels is captured through a mirror on the pallet, and flipped to normal view in post-processing of the image. Only the unique ID with QR-code (at right) needs to be attached after the imaging.

Our new (model year 2021) multi-purpose system combines a large conveyor system with the macro-imaging techniques of the small insect system. Our large system can accommodate six or more operators. Their combined efforts result in 1500 digitized insects in a 7-hour work shift.